Publications

A full list of our publications can be found on: https://scholar.google.com/citations?user=w_6hEzkAAAAJ&hl=en

The following shows the most representative papers published in recent years.

Oxygen Vacancy-Induced Interfacial Lanthanum Hydride and Hydroxide Bifunctional Sites for Selective Hydrogenolysis of Furanic Compounds to Alkyl Diols

Zhang Y, Xue H, Cheng M, Yang X, Zhang Z, Zhao X, Rezayan A, Han D, Wu Dan, Xu C

Abstract: Selective hydrogenolysis of C–O bonds in biomass-derived oxygenated molecules is of great significance for the conversion of biomass to chemicals and fuels, especially for the inert C–O–C bonds in tetrahydrofuran rings. However, the lack of precise active sites results in the low activity of this reaction. In this work, the metal–support interfacial structure of the Ni–La2O3 catalyst was well-controlled by reducing LaNiO3 perovskite at different temperatures. During the reduction, the exsolution and segregation of Ni in the LaNiO3 perovskite led to the formation of metallic Ni nanoparticles and interfacial oxygen-vacant Ni2+-Ov-La3+ sites. Hydrogen spillover from Ni nanoparticles to the interface promoted the in situ generation of La–OH species under reaction conditions. At the same time, the oxygen vacancies at the interfacial Ni2+-Ov-La3+ sites can accommodate the spilled H, inducing the formation of the La–H species. The hydroxyl group in tetrahydrofurfuryl alcohol (THFA) interacted with La–OH through a metal alkoxide intermediate, which was subsequently hydrogenolyzed by the La–H to produce 1,5-pentanediol (1,5-PeD). The intimate La–H and La–OH bifunctional sites on the metal–support interface have a strong synergistic effect, endowing the Ni–La2O3 catalyst with a high THFA hydrogenolysis activity. The proposed interfacial La–H assisted C–O bond hydrogenolysis provides an idea for the design of efficient hydrodeoxygenation catalysts for biomass upgrading.

Key techno-economic barriers in the valorisation of organic solid wastes for chemical production

Mou J-H, Qin Z-H, Chen SS, Leu S-Y, Tsang DCW, Lam JC-H, Zhao J, Yuan Z, Xu C, Lin CSK

Abstract: The utilization of waste feedstocks has potential for sustainable chemical production, yet its industrial scalability is hindered by techno-economic barriers associated with the valorization roadmap. Cooperation among industry stakeholders, research institutions, and government bodies is critical for the establishment of the green and sustainable production of waste-derived chemical products.

Reengineering Wood into a High-Strength, and Lightweight Bio-Composite Material for Structural Applications

Beims RF, Rizkalla A, Kermanshahi-pour A, Xu CC

Abstract: The preparation of wood composites involves long preparation steps and non-renewable matrices while generating lignin waste without high-value utilization. Here, we present a reengineering approach to developing a high-strength and lightweight bio-composite material through fractionating natural wood into highly porous delignified wood (DW) and lignin, synthesis of a lignin-based epoxy resin (LER), followed by composting the DW and the LER. The newly developed wood-based composite has drastically improved properties of hydrophobicity, antioxidation and thermal stability, and more notably extraordinary mechanical properties superior to many metal alloys. Hence the reengineered wood composite developed can be a renewable functional material for structural applications.

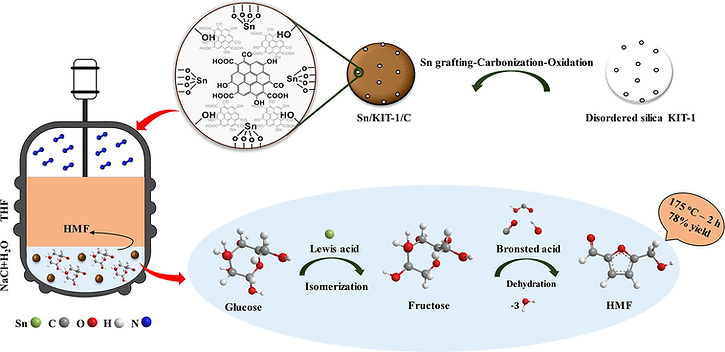

Synthesis of bifunctional tin-based silica-carbon catalysts, Sn/KIT-1/C, with tunable acid sites for the catalytic transformation of glucose into 5-hydroxymethylfurfural

Rezayan A, Wang K, Nie R, Lu T, Wang J, Zhang Y, Xu CC

Abstract: Catalytic transformation of carbohydrates to bio-chemicals such as 5-Hydroxymethylfurfural (HMF) has become a hot research topic, but development of cost-effective/efficient catalysts and processes remains a challenge for industrial application. In this study, efficient bifunctional Sn/KIT-1/C catalysts with controllable acid sites were synthesized and applied for glucose-to-HMF conversion. Strong Lewis acid sites were introduced into the framework of disordered mesoporous silica by liquid-phase grafting of tin chloride, and Bronsted acid sites were generated by inserting carbon into the mesopores, followed by controlled oxidation of the carbon. Characterizations revealed that optimizing the amount of carbon source, and carbonization and oxidation temperature provided a proper amount and strength of acidity that could significantly catalyze glucose dehydration reaction to HMF with suppressed byproducts formation. The best catalyst Sn/KIT-1/C(75–400-300) demonstrated superior catalytic performance at 175 °C for 2 h under THF/H2O biphasic system, obtaining 78.4 ± 2.1% and 82.9 ± 2.4% HMF yield and selectivity, respectively. The high activity may be attributed to catalyst high surface area/porosity, and the presence of well-balanced amounts and strength of Lewis/Bronsted acid sites. The catalyst could maintain its excellent catalytic activity for five consecutive runs, suggesting the high physical–chemical stability of the catalyst. The results obtained in this work demonstrated that bifunctional metal-supported silica–carbon composites can be a promising catalyst for simple/complex carbohydrates conversion to HMF/bio-based chemicals.

Nitrogen-doped carbon: A metal-free catalyst for selective oxidation of crude 5-hydroxymethylfurfural obtained from high fructose corn syrup (HFCS-90) to 2,5Furandicarboxylic acid (FDCA)

Rao KTV, Hu Y, Yuan Z, Zhang Y, Xu C

Abstract: In recent years, development of inexpensive and environmentally benign processes for catalytic conversion of lignocellulose biomass or biomass-derived carbohydrates into platform chemicals has gained increasing attention while also facing technological challenges related to the higher production costs. Here, we synthesized an inexpensive nitrogen-doped carbon (NC) materials by carbonization of bamboo sawdust mixed with melamine and K2CO3. The as-prepared NC materials were used first-time as catalysts for the selective oxidation of crude 5-HMF obtained from HFCS-90 into FDCA. Based on the obtained catalyst characterization and activity results, the rate of formation of FDCA is mainly dependent on the carbonization temperature of the catalyst, the quantity of graphitic N, and its related lattice defects in the carbon matrix. Under the optimized reaction conditions (NC-700 catalyst, 160 °C, 6 h, and 2 MPa O2), the reaction obtained 100% HMF conversion and 83% FDCA yield using crude 5-HMF (88% purity).

Efficient and switchable production of bio-diol/triol chemicals from 5-hydroxymethylfurfural

Armin Rezayan, Dan Wu, Zhen Zhang, Xiaomeng Yang, Renfeng Nie, Tianliang Lu, Jianshe Wang, Xiaoqin Si, Yongsheng Zhang and Charles Chunbao Xu

Abstract: 5-hydroxymethylfurfural (HMF), regarded as one of the top bio-based platform chemicals, possesses a molecular structure with C=O, C-OH, and a furan ring, allowing for conversion into a variety of high value-added green chemicals through a range of catalytic reactions. This study focuses on the highly promising yet challenging conversion of HMF into furanic and non-furanic chemicals with tunable selectivity via hydrogenation/hydrogenolysis over cobalt-copper-aluminum layered double oxide (CoxCuAl LDO) catalysts. The synthesized CoxCuAl catalysts were meticulously characterized and then utilized for the efficient transformation of HMF into 2,5-bis(hydroxymethyl)furan (BHMF) and 1,2,6-hexanetriol (1,2,6-HTO). The CoAl, CuAl, and physically mixed CoAl+CuAl catalysts, predominantly favored BHMF production via hydrogenation of HMF’s carbonyl group. However, the optimal Co5CuAl catalyst achieved efficient and switchable production of BHMF (91.1% yield) or 1,2,6-HTO (72.4% yield) under tunable reaction conditions, owing to the synergistic effects of CoCu on adjusting electronic-geometric properties, where the electron-enriched Co facilitated ring-opening hydrogenolysis. Density functional theory (DFT) calculations and experimental studies disclosed that the bimetallic catalyst outperformed its monometallic counterpart in terms of HMF and H adsorption can be attributed to the formation of the CoCu alloy, inducing a modified d-band center. The findings and future development of this work would lead to sustainable production of high value-added bio-diols/triols from bioresources.

Green coal and lubricant via hydrogen-free hydrothermal liquefaction of biomass

Abstract: Biocrude derived from biomass via hydrothermal liquefaction (HTL) is a sustainable substitute for petroleum to obtain energy and biochemicals. Upgrading biocrude inevitably faces the trade-off between consuming large amounts of hydrogen via hydrotreating and high yield of solid residue without additional hydrogen. In this work, we report a non-hydrogenated refinery paradigm for nearly complete valorization (~90%), via co-generating green coal and bio-lubricant. The obtained green coal has higher heating values comparable to commercial coals, with a lower fuel ratio and reduced ash content. Viscosity of upgraded vacuum distillate is comparable to that of a lubricant oil. A life cycle assessment confirms 28% reduction in greenhouse gas emission and 35% reduction in energy input of this paradigm compared with conventional hydrotreating biorefinery. This approach presents an environmentally friendly, safe and convenient paradigm for biocrude refining from huge biowaste towards carbon-neutral society.

Sustainable Synthesis of Functional Materials Assisted by Deep Eutectic Solvents for Biomedical, Environmental, and Energy Applications

Yingxia Nie, Yuyue Zhou, Yan Zhang, Dalin Sun, Deyu Wu, Lin Ban, Sonil Nanda, Chunbao Xu, Heng Zhang

Abstract: The rapid expansion of the global economy has led to a surge in energy demand, resulting in significant environmental pollution and energy scarcity due to the concomitant increase in greenhouse gas emissions. The advancement of deep eutectic solvents (DESs) has introduced a viable substitute for traditional solvents and processing methods, boasting numerous intrinsic benefits, such as superior eco-compatibility, outstanding thermal stability, and desirable electrochemical properties. Consequently, DESs have garnered significant attention from the research community, demonstrating a broad spectrum of prospective applications in a variety of fields for instance energy, biomass degradation, materials synthesis, and biomedicine. This review aims to offer a comprehensive and methodical overview of DESs, encompassing their historical development, classification, preparation methodologies, and fundamental physicochemical properties. Furthermore, this review explores the applications of DESs in the synthesis of various functional materials and examines their multifunctional roles. Crucially, the economic viability of DESs for environmental and energy applications is thoroughly examined, including an assessment of their cost-effectiveness and market potential. Finally, the review concludes by outlining future research directions for DESs development and the challenges that remain.